Elevator Modernization: Upgrading Geared Traction Elevators

Elevator modernization often involves upgrading geared traction elevators, which are commonly used in mid-rise buildings and operate at speeds ranging from 200 to 500 feet per minute. These elevators feature a drive sheave connected to the motor via a gear train, with power transmitted through reduction gears. Geared traction elevators are more susceptible to wear and tear compared to gearless elevators, due to their bronze spiral worm gear and bronze ring gear, which mesh at very tight clearances.

Importance of Maintenance in Elevator Modernization

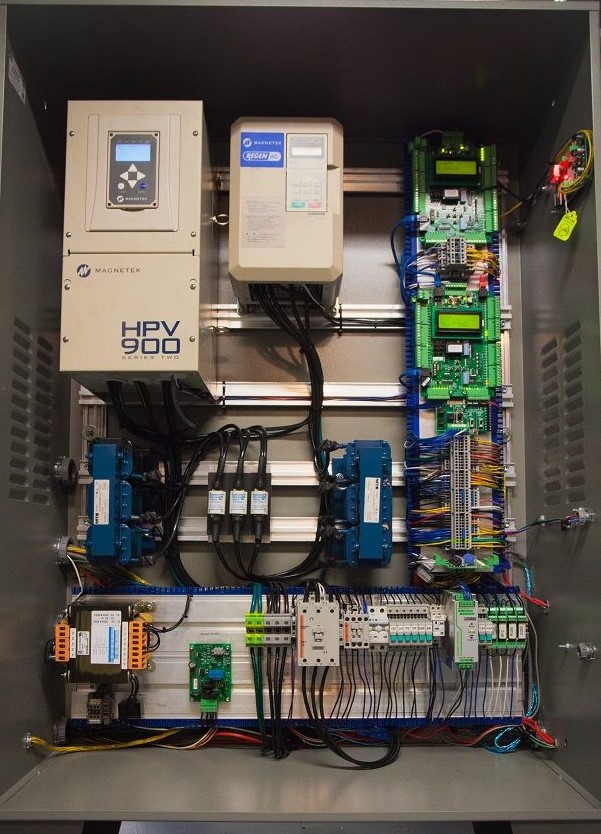

Maintaining proper tolerances is critical in elevator modernization. Bearings and gears in geared traction elevators can wear out, leading to heat, pitting, rumbling, friction, and undesirable noise. This wear often necessitates reducing machine speed to prevent further damage. During elevator modernization, replacing outdated geared machines with newer or more reliable models is a common practice. Many older designs are considered obsolete and may not be worth retaining. Our team assesses the condition of your elevators and provides recommendations for refurbishment or replacement as needed.

The Shift from Geared Winding Drum Elevators in Elevator Modernization

Geared winding drum elevators, which typically serve mid-rise buildings with speeds between 50 and 150 feet per minute, are no longer installed for public passenger use. These machines connect car and counterweight pulley drums to the motor through a gear train and reduction gears. Similar to geared traction elevators, geared winding drum elevators are prone to wear and tear, with their bronze worm and ring gears requiring meticulous maintenance to avoid issues like heat, pitting, rumbling, friction, and noise.

Upgrading Geared Winding Drum Elevators During Modernization

In the context of elevator modernization, replacing outdated geared winding drum machines is a common approach. These machines are often removed and replaced with new geared or gearless traction systems, which may require significant structural modifications to the building. Given their outdated design, geared winding drum machines rarely warrant retention. Our elevator modernization services include a thorough assessment of your equipment to recommend the best options for refurbishment or replacement, ensuring improved performance and reliability.