Major components considered for mechanical upgrade:

ELEVATOR PUMP UNITS:

Submersible Pump Units:

- Flows from 8.3 GPM to 255 GPM

- All components are enclosed within the tank

- Every tank is leak tested

- Hinged top/front door on the submersible unit provides easy access to controls for adjusting and maintenance

- Motor and pump are isolated by vibration dampening mounts. Outlet locations are available as requested

STANDARD TANK SIZES:

|

W x D x H

33 x 18 x 48 38 x 20 x 48 42 x 26 x 48 48 x 30 x 48 |

Standard Equipment:

- Imperial Electric

- Lincoln Motors – 5, 7-1/2, & 10 HP

- Single & Three Phase available

- Maxton Valves

- IMO & Allweiler pumps

- Bore-Max Silencers

- Seismic anchoring mounts

- 20” level sight gauge

- Vented cover

- Isolation mounts between motor/pump & frame

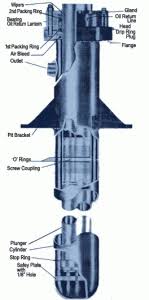

HYDRAULIC JACK:

When considering a hydraulic elevator modernization we will assess the age, condition and operation of jack assembly components to determine if upgrade or replacements are recommended. Recent Code changes have required or recommend replacement of jack assemblies installed prior to 1972.

CONTROL VALVE: